Explore Leading Industrial Brands

Top Brands We Supply

Authorized & Trusted Brands

Explore Leading Industrial Brands

Top Brands We Supply

Authorized & Trusted Brands

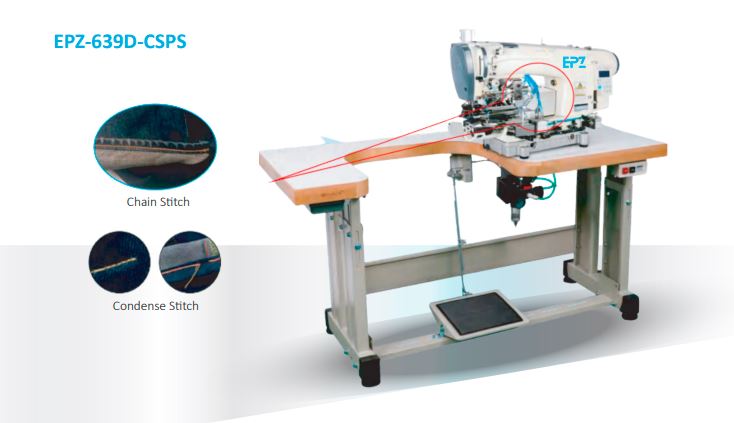

Explore Leading Industrial Brands

Top Brands We Supply

Authorized & Trusted Brands